Congratulations to Edwin in the Netherlands on working through a problem and creating a very successful well!

As you will soon see, he is a very ingenious guy. He wrote me this email:

Hi Mike,

First of all, what a fantastic website you have!

Once my house was ready the garden was the next up in line with a new lawn, trees and flower borders. However my water bill kept adding up and from that time i was dreaming of my own waterwell. Asked a professional company to drill a well, the company’s that did respond said it was

A. Not possible at my property because of the high amount of salt in the layers (we live in a area where we are below sea level and the sea is approx 300m from where the well needed to come.

B. No time to do it

C. Offered to do it for €3.500,-

So finally i decided to start drilling with a friend of mine. Got al the bits and pieces together and started. The 75mm pip got stuck at 8m, but i knew this was the beginning of the sand layer where i wanted to place my well screen in. There was no change to get the 75mm pipe moving again, so we decided to prepare a 50mm pipe, with drill head AND after 40cm a well pipe. We put down this 50mm pipe, lowered a hose with high pressure water to the bottom and where able to lower the 50mm pipe another 2 meters. So far so good. After we started pumping a head enough water and the well was working really good, however lots and lots of sand where coming up. Turned out that sand layer was driven up the pipe once we started pumping.

So, with a 16mm pipe we were able to quickly suck the sand out of the bottom of the pipe (normally it takes a while before the sand comes up the pipe), took the 16mm pipe out and put gravel in there (approx 20cm). Once the pea gravel was in, i threw approx 20cm of “filter glass” in there.

I will send you a video later on

Met vriendelijke groet / Best regards,

Edwin

He included these two photographs:

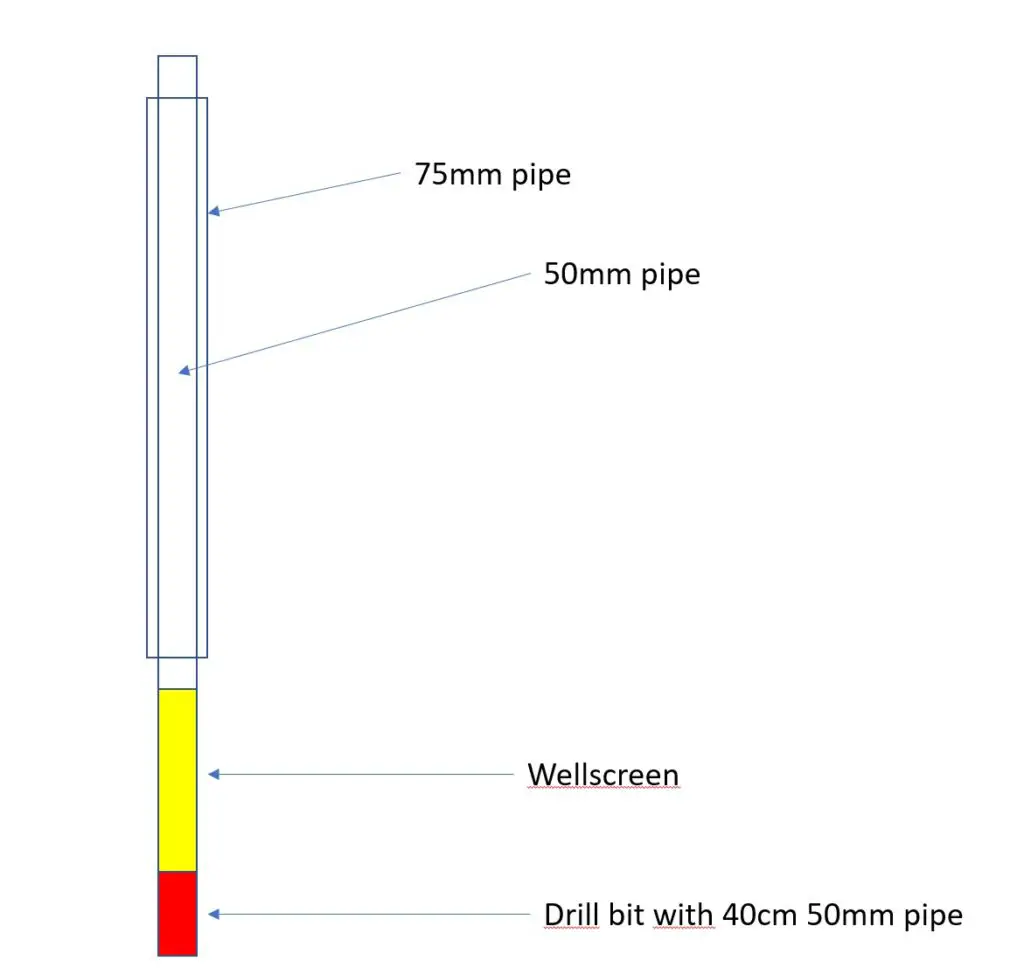

Edwin ran into a problem that is not uncommon. After drilling as far as he could with one 75mm pipe, it stuck. He needed to drill further to put a smaller 50mm pipe with a wellscreen on it. This would give him a 50mm wellscreen exposed to the water bearing sand that was just beyond the bottom of his drillpipe.

He put a 50mm wellscreen pipe all the way to the bottom inside of his stuck 75mm drillpipe. Then he ran a small flexible pipe (a small hose) down the middle of the 50 mm pipe and connected it to a pressurized water source like a hose bib. He used the small hose to wash sand off the bottom of the hole until he could work his 50mm wellscreen pipe down far enough to expose his wellscreen below his 75mm drillpipe.

He attached a pump to and pumped water and sand off the bottom of the well until he got all the loose sand out. Then he raised the wellscreen pipe slightly as he dumped a layer of gravel, then a layer of filter glass (https://www.amazon.com/Filter-Glass-40-Lbs-Bag/dp/B00WES8YGS), then another layer of gravel.

So, when he was done he had his screen in water bearing sand AND he could get water from the bottom of his pipe as well as he had essentially created a screen for the bottom through his layers of gravel/filter glass/gravel.

Pretty darn slick, eh!!?

He described it as follows:

As my 75mm pipe got stuck and i needed to drill deeper i decided to lower the 50mm pipe (with wellscreen already mounted and under the wellscreen 40cm pipe with a drilbit) inside the 75mm pipe. As the wellscreen was already on this 50mm pipe i could no longer use the normal drill head because all the water would go through te wellscreen instead of flowing down and put pressure on the material underneath the drill bit. So i decided to lower a pressure hose upon the sand through the 50mm pipe. Then i started drilling again, as i was on the sand already it was quite easy to lower the 50mm pipe another 1,5 meters.

After that my wellscreen was working. However, as the 50mm pipe was open at the bottom, sand kept pouring in on the bottom of the pipe mixing with the water which got in via the well pipe. Also the sand level would rise through the red part in the drawing above up to 20cm into the well pipe.

So i decided to quickly get the sand out of the red part (just sucking it up with my pump) and just throw 1 layer of gravel into the 50mm pipe, then a layer of filter glass and last again 1 layer of gravel while slightly lifting the 50mm pipe. From that point on i had crystal clear water and a quite good capacity. What i think now is dat water is not only flowing through the well pipe but also from the bottom through the “self made” filter layers.

To be honest i am still amazed that this whole drilling adventure actually worked and i have now my own well for just a couple of 100 euros (or dollars 😉 )

Will make some photos for you tonight,

Met vriendelijke groet / Best regards,

Edwin

Here is the diagram he sent explaining his technique:

He also furnished these photographs and videos:

Edwin also included these videos of his well in action!

Edwin’s Success! story is exactly what I’m talking about when I say that at this point most of the ideas and techniques appearing on these pages are not mine. They are yours, the users of this site. Thanks again Edwin!

drillyourownwell.com

drillyourownwell.com