I waited a long time to post this page. The reason is I am not terribly happy with the design of my handle. It requires the regular replacement of the pipe clamps. They wear out. I’ve done over a dozen experiments with other types of clamps over the years but they never worked out. The problem is the sturdier clamps won’t fit over the PVC couplers. For example, a muffler clamp works great and is plenty sturdy. Problem is, when you add a stick of pipe you need to slide it up over the PVC coupler and it just won’t go. Anyway, I have answered well over 100 emails asking about how to make the handle, so here it is.

The handle works ok with two pipe clamps and many of the pictures only show two clamps but I suggest you use four. When you get to a critical point and you really need to heft the pipe up those two extra clamps can be critical.

Below are several pictures of the handle that I trust will assist you in making one. If you make one you are particularly happy with please send me pictures!

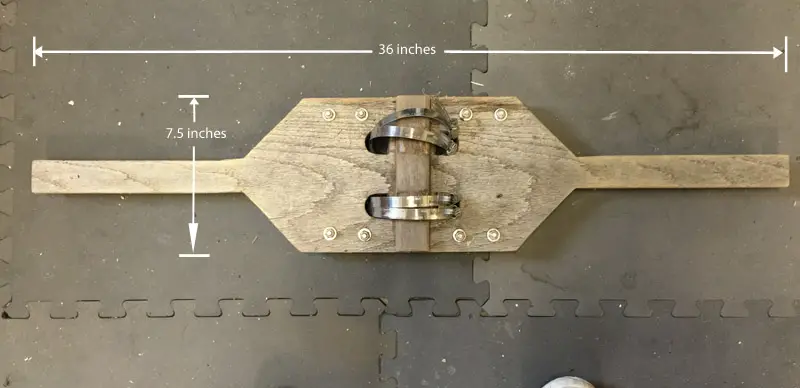

Handle Installed with two pipe clamps and ready to use.

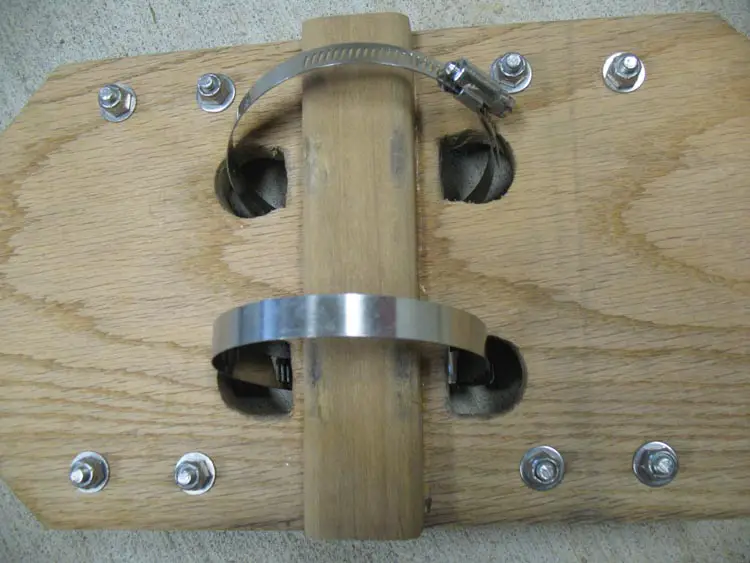

Closer view of outside section of handle.

The vertical wood spacer is to relieve stress on the pipe clamps

Closer view of inside section of handle. This side holds the PVC pipe.

Inside section of handle. This side holds the PVC pipe.

Overall Measurements

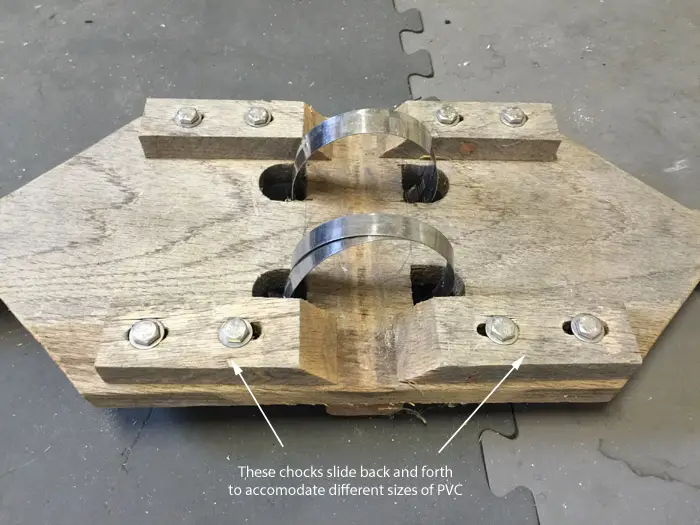

Detail showing adjustable chocks

For particularly stressful jobs like pipe removal, the handle can be combined with rubber sleeves.

In the pictures above my handle is 36 inches long. I’m still using it at that length but I think if I was making a new one I might make it 32 to 34 inches long. Experience suggests the extra length is not needed. Be sure and include the adjustable chocks on yours. Frequently you wind up drilling with multiple sizes of pipe even though you never planned to.

drillyourownwell.com

drillyourownwell.com